Precise Motion Control in Meat Processing Applications

KOLLMORGEN showcases distributed servo solutions at the IFFA in Frankfurt

If all the drive technology for a food processing application uses just a single cable, then servo control can be integrated and connected up without requiring too much space or time-consuming installation work. KOLLMORGEN will be showing what this kind of distributed setup might look like in practice and why even machines with completely different tasks from a range of manufacturers can be connected together during the IFFA international meat processing fair to be held between May 7 and 12, 2016, in Frankfurt (Hall 11, Stand D21).

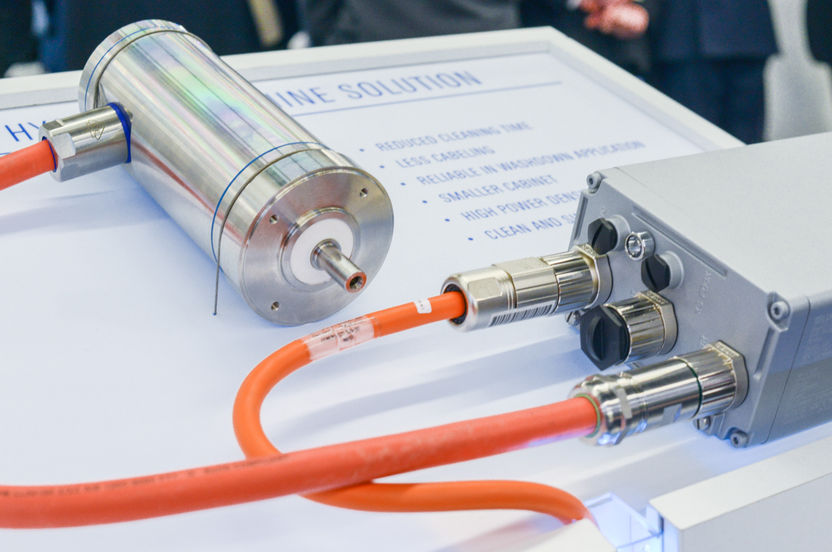

AKMH stainless steel servo motor with a distributed AKD-N washdown servo drive

KOLLMORGEN

Distributed AKD-N servo controller

KOLLMORGEN

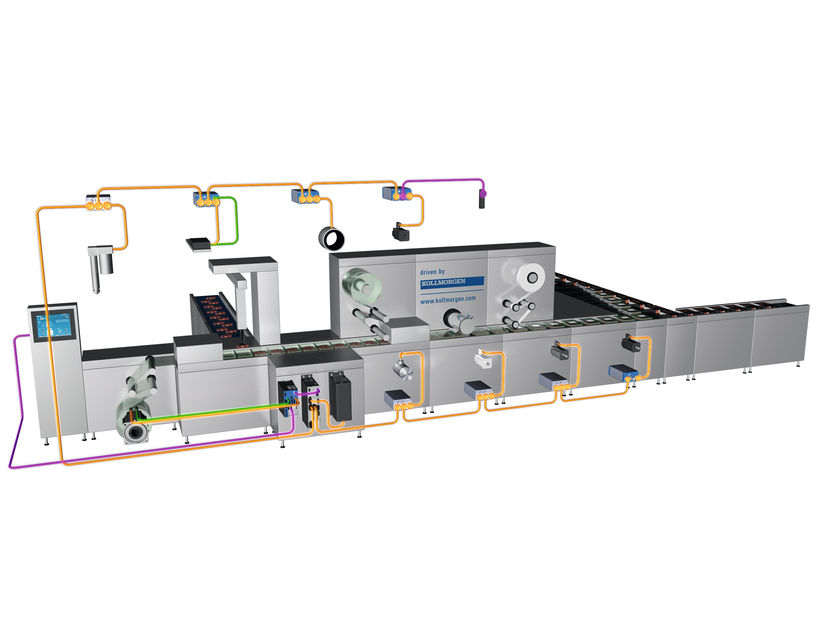

Visualization of a packaging machine line involving a decentralized motion control solution

KOLLMORGEN

From production to packaging technology, KOLLMORGEN will be keeping various machines under tight control during the IFFA and combining them into an efficient production network. In doing so, the specialists in servo drive technology and motion control will illustrate the kinds of efficiency improvements you can achieve with decentralized solutions – in terms of installation alone. Thanks to its compactness and IP65 degree of protection, the decentralized servo technology offered by the AKD-N range of controllers is now mature enough to be used basically anywhere. And as a development of this, KOLLMORGEN will also be showing off a special version in Frankfurt featuring a washdown coating for use in food industry applications involving no direct contact with the product.

The new technology offers new possibilities, with the additional prospect in future of establishing communicative networks for connecting dencentralized drive solutions with the control level (pretty much regardless of the manufacturers involved). KOLLMORGEN has developed a revolutionary multi-language interface for this purpose. This makes it possible to connect motion control applications – via software alone – with all the established real-time Ethernet systems now deemed indispensable to the highly dynamic food industry.

Most read news

Other news from the department research and development

Get the food & beverage industry in your inbox

From now on, don't miss a thing: Our newsletter for the food & beverage sector brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.