OMIRA brings CFA 812 from SIG Combibloc into operation

combifitMidi new on the German market

OMIRA Oberland-Milchverwertung GmbH has now brought a CFA 812 filling machine from SIG Combibloc into operation at its Neuburg factory. The machine can fill products in the carton packs combiblocMidi and combifitMidi. This format is now available in Germany for the first time. Various products of the brand ‘MinusL’, which are made especially for people suffering from lactose intolerance, are now offered in combifitMidi 1,000 ml – and more are planned.

OMIRA Oberland-Milchverwertung GmbH has now brought a CFA 812 filling machine from SIG Combibloc into operation at its Neuburg factory. The machine can fill products in the carton packs combiblocMidi and combifitMidi. This format is now available in Germany for the first time. Various products of the brand ‘MinusL’, which are made especially for people suffering from lactose intolerance, are now offered in combifitMidi 1,000 ml – and more are planned.

SIG Combibloc

For more than 10 years, OMIRA’s ‘MinusL’ brand has been the leader in the lactose-free dairy products segment in Germany. OMIRA is now packaging various types of milk and lactose-free dairy products in a range of fat content grades in the combifitMidi 1,000 ml aseptic carton pack with combiSwift screw cap from SIG Combibloc – an innovation on the German market.

OMIRA

The OMIRA group, an association of about 3,000 dairy producers from the Lake Constance, Black Forest, Schwabian Alb, Allgäu and Vorarlberg regions, processes around a billion kilogrammes of milk per annum. The organisation employs more than 500 people, who use state-of-the-art technology to produce a wide range of dairy products, as well as semi-finished goods for the food and confectionery industry.

The organisation’s portfolio also includes lactose-free dairy products. For more than 10 years, OMIRA’s ‘MinusL’ brand has been the leader in the lactose-free dairy products segment in Germany. Christoph Brändle, Head of Sales at OMIRA: “Every seventh German is intolerant to lactose, because the body doesn’t produce the enzyme lactase or produces too little of it. In these people, the lactose can’t be broken down into its components, glucose and galactose. The consequence of consuming dairy products can be massive physical discomfort. However, we’ve been able to reduce the original lactose content of cow’s milk from around 4.8 grammes per 100 grammes of milk to less than 0.1 grammes per 100 grammes. Our ‘MinusL’ products, which can be consumed by people with a lactose intolerance, are based on this milk with significantly reduced lactose content”.

Innovation in Germany

OMIRA is now packaging various types of milk and lactose-free dairy products in a range of fat content grades in combifitMidi 1,000 ml with combiSwift screw cap from SIG Combibloc – an innovation on the German market.

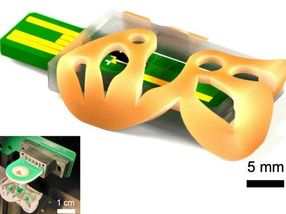

The combifit carton format series features sturdy, slender carton packs that are curved outward at the front and inward at the back, so they sit very comfortably in the hand. The sloping top characteristic of combifit gives an optimal pouring angle. The user-friendly features of the carton pack are topped off by the combiSwift screw cap, which has a very easy opening action and can be securely re-closed after initial opening, so the product is safely protected even after the seal has been broken.

The combifit product range includes four different format series. In addition to combifitPremium (available in 500, 750 and 1,000 ml), combifitMagnum (1,500 ml) and combifitSmall (200, 250, 300, 330 and 350 ml), combifitMidi (500, 750 and 1,000 ml) is now also available on the German market. combifitMidi has a large 70x72 millimetre base, giving the carton pack optimal stability. It is the ideal choice to give special products the right appearance and optimal protection.

The filling machine CFA 812 from SIG Combibloc that has been installed at the OMIRA factory in Neuburg has an output of up to 12,000 carton packs per hour. It can be used to fill combibloc and combifit formats with the same base dimensions. The filling process is the same for both formats; only the carton sleeves in the filling machine magazine are changed. Switching between a combibloc and a combifit format with the same base dimensions takes just minutes. There is no need to change any machine parts. After the filling process has taken place and the carton pack has been sealed, an applicator gives the carton pack its characteristic shape and fits the closures.

And in terms of volume, as well, the CFA 812 offers unrivalled flexibility if the carton packs have the same base dimensions – just like all other filling machines from SIG Combibloc. In just a few steps, the filling machines can be adjusted for a particular volume and set via touch-screen monitor. Even when switching volumes, there is no need to resterilise the machine or change machine parts.

Alois Keller, business unit manager Production and Technology at OMIRA: “We at the OMIRA group were impressed by the flexibility of the SIG Combibloc filling machines. We’re already able to bring out a wide range of products in the innovative combifitMidi carton pack – more products are already planned. And we’ll also benefit from the format and volume flexibility of the CFA 812”.