UHT processing of innovative drinksplus products in practical tests: new Stork UHT in SIG Combibloc’s combiLab

UHT processing of innovative drinksplus products in practical tests: new Stork UHT in SIG Combibloc’s combiLab

A new Sterideal ST5T-SPEC UHT heat exchanger unit, suppliedby JBT Corporation’s Stork Food & Dairy Systems business unit, has now been added to the equipment in the filling machine pilot plant at SIG Combibloc’s combiLab. The state-of-the-art system is ideal for processing drinksplus products containing perceptible extras such as pieces of fruit and vegetables or Cereal grains, before the beverages are then aseptically filled in carton packs from SIG Combibloc.

A new Sterideal ST5T-SPEC UHT heat exchanger unit, supplied by JBT Corporation’s Stork Food & Dairy Systems business unit, has now been added to the equipment in the filling machine pilot plant at SIG Combibloc’s combiLab.

SIG International Services GmbH

The state-of-the-art system is ideal for processing drinksplus products containing perceptible extras such as pieces of fruit and vegetables or cereal grains, before the beverages are then aseptically filled in carton packs from SIG Combibloc.

SIG International Services GmbH

Experts from all sectors of the beverage sector recently came together at the ‘BevTech Europe’ conference of the International Society of Beverage Technologists (ISBT). The host this time was SIG Combibloc.

SIG International Services GmbH

In the combiLab, product developments such as new drinksplus concepts, and developments relating to filling technology, are tested under practical conditions. This service helps turn product ideas into success stories.

The new Stork UHT has just been showcased at the International Society of Beverage Technologists (ISBT) ‘BevTech Europe’ conference, which was jointly sponsored by Stork and SIG Combibloc and was held at SIG Combibloc in Linnich (Germany).Dr Sven Fischer, Global Technology Director at SIG Combibloc: “We’re pleased to have been able to welcome many members of the ISBT, along with guests from our customer base. There was a lot of positive feedback for the mix of presentations, exchanges of experience and insights into actual practice that we were able to offer in our combiLab”.

The ISBT was founded in 1952 as a platform for information exchange and knowledge transfer in the field of beverage technology. The association, set up in Washington, D.C., now has more than 1,000 members.It is the only organisation in the world dedicated to the scientific and technical aspects of the development, processing and filling technology, packaging and distribution of non-alcoholic beverages. Its members include beverage technologists, scientists and beverage manufacturers, as well as suppliers to the beverage industry engaged in technical and scientific positions.

Close network of experts

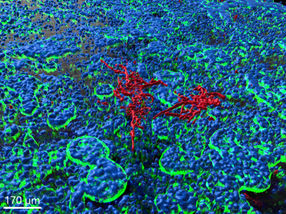

Dr Sven Fischer: “Hosting this year’s BevTech Europe conference gave SIG Combibloc the opportunity to present our combiLab portfolio to a top-class professional audience, and closely linked to that we also showcased our experience and our current projects relating to the drinksplus technology. Using this technology, beverages containing up to ten per cent natural particulates can be processed and aseptically filled in carton packs using SIG Combibloc’s standard filling machines for liquid dairy products and non-carbonated soft drinks.The individual bits in the beverages can be up to six millimetres in size.In the wide-ranging group of experts, we had brought together the right specialists from all sectors of the beverage industry, and we’re proud to offer our customers real added value with a close network of noted experts”.

In the filling machine pilot plant of SIG Combibloc’s combiLab, the focus is on new product developments and reworkings and further enhancements relating to the aseptic filling system, with testing under real conditions. The aim is to quickly and flexibly test prototypes of packaging materials, filling machines, carton packs and new product concepts, perform targeted test series and carry out test fillings, and provide authoritative information on the entire packaging system and the filling process, for internal projects and for customers of SIG Combibloc.The combiLab is extensively equipped for these purposes – with equipment for product processing and aseptic filling machines for beverages and food. Applicators for closures and downstream equipment are also part of the range.

High degree of automation

The new UHT heat exchanger unit from Stork adds to the facilities in the combiLab and complements the existing possibilities.Rudolf Flörke,Head of Aseptic Technology at SIG Combibloc: “The Stork UHT Sterideal ST5T-SPEC in our combiLab is a higher-performance model than our previous UHT system, and allows for the flexible requirements with regard to the heat treatment of a wide range of products. In addition, it has a much higher degree of automation. Customers who use our services in the combiLab will also benefit from these advantages, when they work with us to develop and manufacture innovative product concepts under real conditions, and test the process technology”.

With the new Stork UHT and its possibilities with regards to the aseptic filling of innovative beverages with particulate content, the course for the future has been set. ‘Inclusions’ were a key topic at ‘BevTech Europe’.Dr Sven Fischer says: “Especially in the field of beverages containing perceptible product particulates – known as ‘inclusions’ – we should expect quite a few things in the future. Beverages that you don’t just drink, but can also in a sense chew, have now found their way from Asia into various parts of the world, and are seeing very positive development. All kinds of new combinations are possible, and with our technology they’re feasible as well”.