Robots Designed for Hygiene

Machines according to EHEDG-guidelines

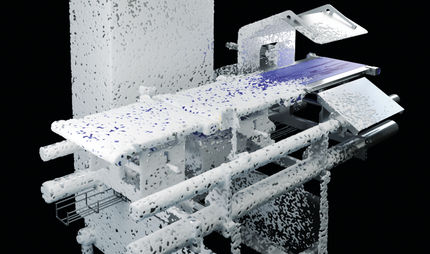

Robots are steadily taking over in the food industry, and that includes even sensitive work on unwrapped products. A word of caution, however: standard robots are completely unsuitable for production where microbiological contamination must be avoided. In such circumstances, machinery and equipment has to comply with EHEDG guidelines.

The European Hygienic Engineering and Design Group, an association of equipment manufacturers to the foodprocessing industry, food processing companies, research institutes and public health institutions, has been working on this issue for more than 25 years. EHEDG not only focuses on hygiene measures in the production and packaging of foodstuffs but also draws up appropriate guidelines.

Of particular interest to food producers is, of course, the question of how robot kinematics used in the food sector measure up to the criteria of design for hygiene. Fouraxis robots, articulated robots and delta kinematics – what are the arguments for or against their use in various applications?

Download white paper now

Robots Designed for Hygiene

Machines according to EHEDG-guidelines

See the theme worlds for related content

Topic world Hygiene

Hygiene is the foundation of the food and beverage industry. Hygiene technology ensures that products are not only tasty, but most importantly, safe for consumption. From advanced cleaning processes to sterile filling techniques, the industry is constantly setting new standards to prevent contamination and the growth of microorganisms.

Topic world Hygiene

Hygiene is the foundation of the food and beverage industry. Hygiene technology ensures that products are not only tasty, but most importantly, safe for consumption. From advanced cleaning processes to sterile filling techniques, the industry is constantly setting new standards to prevent contamination and the growth of microorganisms.