Pumps:

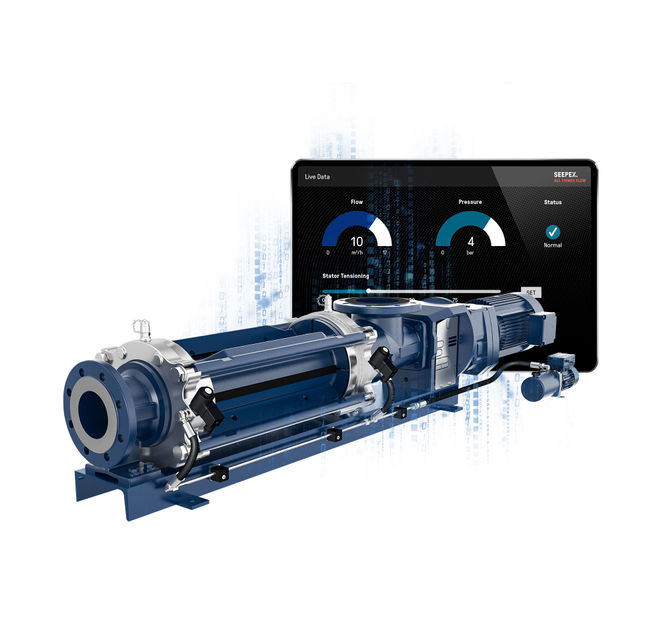

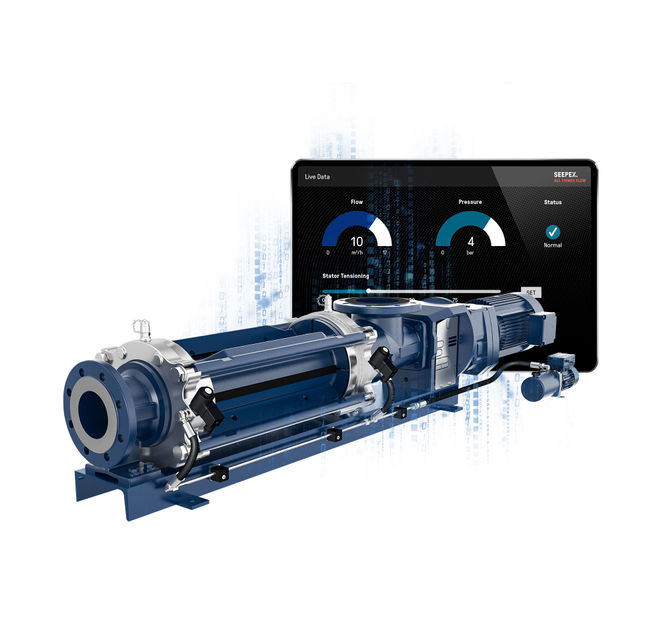

SCT AutoAdjust

SCT AutoAdjust: Only a matter of adjustment

Best conveying capacity and productivity: always operating at the optimal level

Immediate adaption to changing process conditions increases overall efficiency

Reduced downtime through predictive maintenance via cloud connection

With SCT AutoAdjust easily set the stator clamping to the optimal operating point

SCT AutoAdjust (SCT AA) is a pump which enables the stator clamping to be set automatically, hydraulically und precisely at the push of a button. For a constant conveying capacity und high productivity. Remotely from a control room or locally via SEEPEX Pump Monitor or the app. There is no need to go to the pump anymore, which simplifies the daily work routine. The stator clamping extends the pump's lifetime extremely, thus reducing the lifecycle costs and minimizing need for spare parts. A 24 hour monitoring enables an optimal conveying process. SCT AA is essential in critical applications, which require high operational safety and absolute stability. It can be used in practically every industry and application and for almost all pumping media.

1

SCT AutoAdjust: automatically set optimal operating point

2

Remotely set stator clamping

Request information about SCT AutoAdjust now

Pumps: SCT AutoAdjust

SCT AutoAdjust: Only a matter of adjustment