VEGABAR /VEGAPULS / VEGAPOINT

Level and pressure sensors with colour display for hygienic processes in the food industry

Front-flush process fittings and sealed housings can be CIP-cleaned at up to 150 °C during operation

A unique colour illuminated ring for better visibility from all directions and from a distance

Uniform communication standard IO-Link for fast, intelligent connection to control systems

Hygienic, calibration-free and 150 °C CIP-cleanable – with these food sensors your process runs

How do food production processes meet the highest quality standards while remaining fast and cost effective? By using the right sensor technology. VEGA offers the most suitable level and pressure measurement technology for every food application: to ensure unvarying product quality, ideal hygiene and efficiency – especially in direct contact with food and in CIP cleaning, but also in non-food applications. Featuring reliably protected seals, all-metal housings and perfectly smooth media-contacting surfaces, the sensors have been specially developed for the food industry. They meet all the requirements of food safety – confirmed by EHEDG, FDA and 3-A. The focus is also on costs: with the standardized communication protocol IO-Link and the wide range of available connection options, they can be easily and cost-effectively integrated into existing systems and build upon them. VEGA level and pressure solutions are virtually a synonym for fast processes, high reliability and transparency under all application conditions. And they come with a comprehensive range of services as well.

1

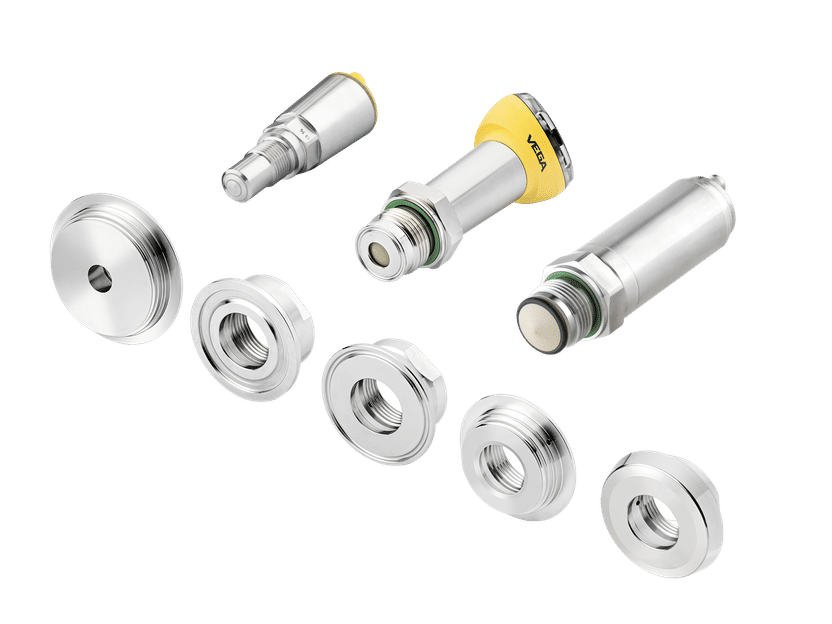

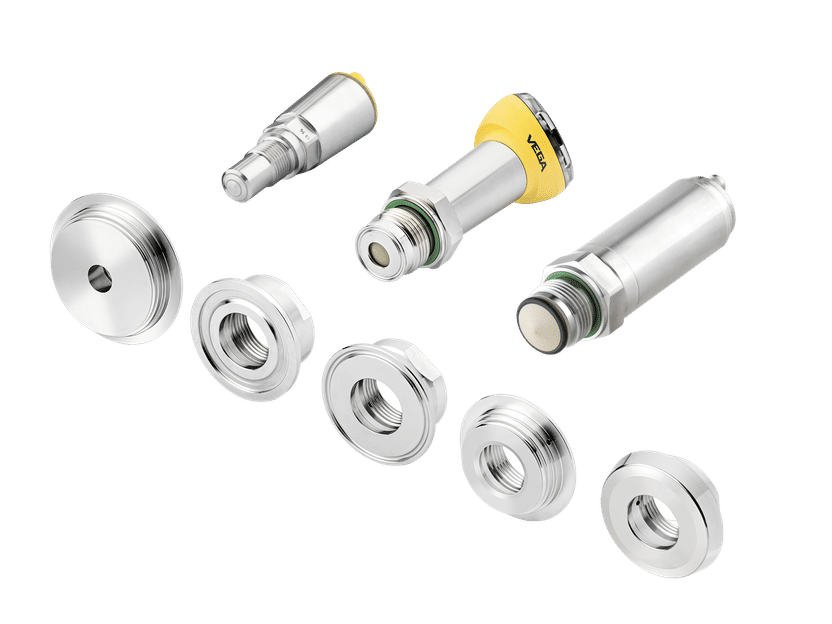

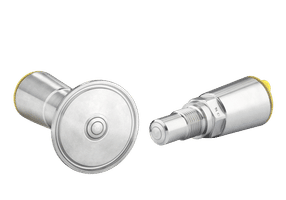

The standardised hygienic adapter system of VEGABAR pressure sensors, VEGAPOINT level switches and VEGAPULS level sensors saves users time and money

2

Specialised in hygienic applications for the food and pharmaceutical industries: The continuous radar level sensor VEGAPULS 42

3

VEGAPOINT level switches protect food production processes from overfilling or dry run – and simultaneously detect oil, water and foam

4

All switching statuses are clearly indicated by the 360° colour display of the VEGABAR pressure sensors.

5

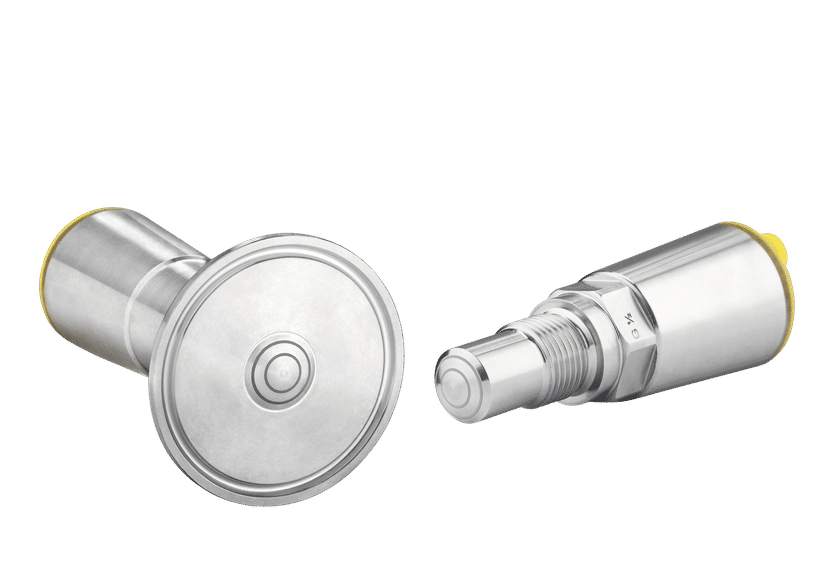

VEGA has developed the front-flush level switch VEGAPOINT 24 especially for use with very sticky, viscous or abrasive products

Request information about VEGABAR /VEGAPULS / VEGAPOINT now

Sensors: VEGABAR /VEGAPULS / VEGAPOINT

Level and pressure sensors with colour display for hygienic processes in the food industry

Product classification VEGABAR /VEGAPULS / VEGAPOINT

Product categories

Applications

Manufacturers of similar products

Advertisement