About ViscoTec

ViscoTec – Perfectly dosed!

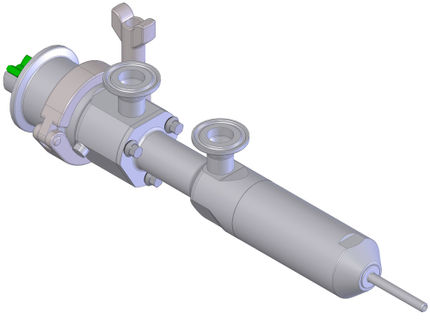

ViscoTec Pumpen- u. Dosiertechnik GmbH manufactures systems required for conveying, dosing, applying, filling and emptying medium to high-viscosity fluids. The technological leader headquarter is in Töging a. Inn (Bavaria). Furthermore, ViscoTec has subsidiaries in the USA, in China, Singapore and in India and employs about 250 people worldwide. Numerous sales partners all over the world complete the international distribution network. Next to technically sophisticated solutions to even the most complicated application, ViscoTec is the single point of contact to deliver all components for a complete system: from emptying to preparing and to dosing. This guarantees successful interaction of all components. All fluids showing a viscosity of up to 7.000.000 mPas can be conveyed and dosed almost pulsation-free and with extremely low shear. ViscoTec offers comprehensive consulting for every application and, if required, extensive tests will be carried out in close cooperation with the customer. The dosing pumps and systems are perfectly adapted to their respective application whether it is the food sector, the automotive industry, the aerospace field, the medical technology, the pharmaceutical industry and many other branches.

Advertisement

Product portfolio of ViscoTec

Here you will find ViscoTec Pumpen- u. Dosiertechnik GmbH

See the theme worlds for related content

Topic world Hygiene

Hygiene is the foundation of the food and beverage industry. Hygiene technology ensures that products are not only tasty, but most importantly, safe for consumption. From advanced cleaning processes to sterile filling techniques, the industry is constantly setting new standards to prevent contamination and the growth of microorganisms.

Topic world Hygiene

Hygiene is the foundation of the food and beverage industry. Hygiene technology ensures that products are not only tasty, but most importantly, safe for consumption. From advanced cleaning processes to sterile filling techniques, the industry is constantly setting new standards to prevent contamination and the growth of microorganisms.