Cocuus manufactures artificial meat cutlets with a 3D printer

Advertisement

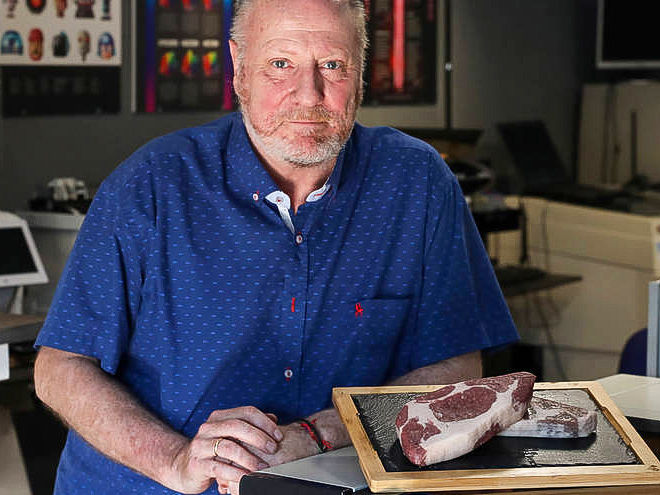

Synthetic meat is manufactured from animal or vegetable substances and looks and tastes similar to real beef chops.

The Navarrese company Cocuus manufactures artificial meat cutlets with a 3D printer

Cocuus

The Navarre-based company Cocuus has succeeded in developing synthetic meat cutlets, manufactured using a 3D printer. The chops, similar in appearance to those that can be found in butcher's shops and not very different in taste, can be made from a substance based on animal cells, which can come from less usable parts of a cow, or they can even be created in a bioreactor, without the need to kill any animal to obtain the meat. In addition, the cutlets may also be composed of vegetable substances, based on peas, making them suitable for consumption by vegetarians. In this case, the appearance is still very similar to that of the real T-bone steak, but the taste is still being refined to be more meat-like, "although it is already good".

The company, which is based in Cizur Menor, presented its chops at the Food for Future congress in Bilbao. But not only their chops. They have also managed to manufacture bacon or lamb ribs in the same way and have been able to replicate the process to develop synthetic salmon fillets. In this way, Cocuus has taken a step forward in the field of artificial foodstuffs, a field with enormous potential. Moreover, the Navarrese company's project has two elements that differentiate it from other similar initiatives. On the one hand, it has devised a food production process based on a two-way journey: from the study of the real cutlet they obtain the data with which they configure the artificial steak. Even more important is possibly the fact that they are going to be able to take meat manufacturing to an industrial scale, thanks to a machine whose patent they will soon apply for and which is capable of producing 10 kilos of synthetic cutlet per minute.

A NEW CHALLENGE

The company Cocuus, which is also involved in robotics technology, already has experience in the field of food and 3D printing. They have designed and marketed a machine that can be used, for example, to print beer foam with a football crest or any other image you want. They have also developed a technology to give purees the appearance of meat or fish dishes. With these arguments, they were one of the four firms selected for Spain Foodtech, a programme to help technological start-ups working in the field of food, and which has the support of a project incubator, Eatable Adventures, and the National Centre for Food Technology and Safety (CNTA). "They asked us if we would be able to create a plant-based steak machine. We said yes," explains Patxi Larumbe Beramendi, CEO of the company.

The process starts with what Larumbe calls the cells, a slurry of meat or vegetable substance from which the chops will be made. In principle, these cells would be formed in bioreactors, in a process in which it is sufficient to take a simple sample from the animal, and there is no need to slaughter it. Its stem cells would be used to construct the fibres from which the artificial meat would then be printed. "The problem," Larumbe points out, is that "they are not yet on the market, because they are in the experimental phase, with no regulatory basis. What can be done is to mimic the process by dissociating meat until it becomes cells. They do this by processes such as grinding, which produces something similar to a slurry that will serve as a raw material. In this case, the meat does come from animals, but with the advantage that less valuable areas can be used, which will later become the cutlet. For the fat they use animal substances or sunflower oil, while the cutlets made from vegetable material are dominated by a pea textured material.

The mixture, obtained "after thousands of formulations", also incorporates binders and other substances that will give it flavour and allow the steak to maintain its solidity even when it withstands high temperatures in the frying pan or on the grill. "There are agents who are working with 12 or 14 ingredients. We use 3 or 4. It is not so processed", says Daniel Rico Aldaz, CMO (marketing director) of a company in which Javier Zaratiegui Fernández works as CTO (chief technology officer). Cocuus started with an investment of two million euros and now has around fifteen employees.

DATA AND FOOD

The heart and soul of the production of chuletones, or ribs and bacon, it doesn't matter, lies in a Cocuus process that Patxi Larumbe calls Food to Data, Data to Food. He starts by subjecting a real chuletón to an axial tomography, a CAT scan. "It's an intense X-ray that allows you to discriminate where there is fat, meat, bone and vascular pathways". These images translate the geography of the meat, its distribution into parameters that a 3D printer can work with. First, in vectors (straight lines, points, planes...), then in a map of three-dimensional objects. From there, the only thing left to do is to transmit to the printer what the final product will look like. Larumbe points out that when they examined the salmon, also with a CAT scan, and studied their musculature, they saw that it could be replicated with a mathematical figure, the hyperbolic parabola, which can be translated with numbers. And if you can do that, the computer and printer can understand it.

So much for the outward journey, from the original meal to the data. Now it's time for the return journey: to sort that data as appropriate, "because we may want the fat layer to be bigger or smaller", feed the printer with that raw material of cells and ask it to make the cutlet. So far they have developed them with a pilot machine, a printer with two extruders, one for meat, one for fat, with which they have manufactured the first pieces. It is a machine with variable geometry, with which they can give the piece different shapes, such as those of beef cutlet, pork bacon or lamb ribs that do not come from the farm. Or pieces of salmon that don't come from the river.

However, the company from Navarre does not want to stop there. "The usual thing in the food industry is to work with standard 3D printers, with a head that makes a fillet in 40 minutes", Larumbe describes. The promoters of Cocuus want to reach industrial levels, for which they have designed a machine with 300 extruders in parallel that simultaneously extract the components and manufacture the part, in a way that is somewhat similar to the way pixels create digital images.

They will soon apply for a patent and hope to have a device capable of producing 10 kilos of plant-based chops per minute ready in a few months. This is the way, says Daniel Rico, to bring this vegetable 'meat' to the market at more competitive prices. And a step towards artificial foods becoming part of our menu. "It could be like when gulas came out 30 years ago", compares Patxi Larumbe. "Many people thought that it was a joke and what almost nobody eats today are elvers".

THE PROCESS, STEP BY STEP

1 Cells. The raw material is a slurry of animal or plant cells. They can be created in bioreactors, from samples of livestock or plants, but this process is still experimental. Therefore, meat or plants such as peas are taken and dissociated.

2 Formulations. It is necessary to determine what is added to these cells so that they bind together and the product does not lose its solidity, as well as to give them the taste closest to that which is to be imitated.

3 From food to data. At the company Cocuus, they study the geometry of natural food by applying a CAT scan that allows them to analyse the exact distribution of different areas and translate them into vector maps and models that printers can understand.

4 From data to food. The data on the geometry of that food, which can be modified to give it other characteristics such as a different thickness of fat layers, is used by the 3D printer to produce the final product.

A MEAT THAT IS EASIER TO BITE AND HAS A SIMILAR FLAVOUR

When you taste the steak that has come out of a 3D printer, the first thing that strikes you is its soft texture, the ease with which you bite into it. "The biggest difference is in the bite. But most people like it to be soft....", says Patxi Larumbe. The flavour, at least for an inexpert taster like the author of the report, is not very different from the original, perhaps not as intense as the chuletones served in steakhouses or restaurants. "It tastes the same, because it's made of meat", Larumbe argues.

Another thing, Larumbe acknowledges, is the cutlet whose ingredients are vegetable, based on peas and fat from sunflower oil. "It tastes a little different but it's good". In any case, the process of rounding off the flavours and the sensation when biting into it is still in progress, a task in which, as in the whole project, they have had the help of the CNTA in San Adrián.

A TECHNOLOGY "TO SOLVE A WORLD PROBLEM".

Daniel Rico believes that technologies such as the one they have developed at Cocuus will "revolutionise the way we feed ourselves in the future. There is already talk that in 2050 there will be no animal pork chops in Spain. It is a trend that could become law". In this sense, synthetic meat is an alternative to reduce intensive livestock farming and its environmental problems. It can also be a way to feed a growing population. "There are not enough cows for 10 billion," Larumbe points out. "If we manage to make factories with bioreactors that produce steaks and meat without the need for cows to enter them, we will solve one of the world's problems. Not to mention that the animal tissues that come out of bioreactors "will have no chemical residues".

This type of food also has a more modest target: vegetarians and vegans. "Many of them long for the special pleasure that meat generates.

Other news from the department research and development

Most read news

More news from our other portals

Something is happening in the food & beverage industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.