GEA makes sustainability KPI controllable for breweries using AI

Pilot projects to improve performance are underway at well-known breweries

Advertisement

GEA has added predictive AI elements to its real-time monitoring for breweries to make brewing processes more sustainable. Developed together with practice partners, GEA InsightPartner Brewery monitors production performance in real time, anticipates anomalies and suggests improvements. In addition to traditional brewhouse data, the system now analyzes sustainability metrics based on energy consumption and heat recovery in the process cycle.

GEA

GEA

GEA

Overcoming data silos

"Driving the sustainability of brewing from production was the driver for this innovation," recalls Dr. Mark Schneeberger, senior director of product development, design and research for GEA's brewing business. "To do this, we need to be able to measure and relate events in our real-world environment. In the second step, we underpinned the software with self-learning AI. Brewers can better understand and solve their problems this way. Brewmasters can brew again instead of analyzing data. GEA InsightPartner Brewery becomes a steering aid for sustainability."

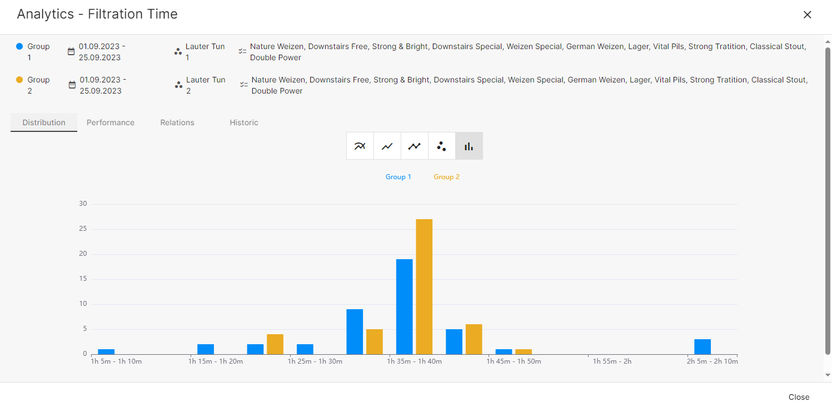

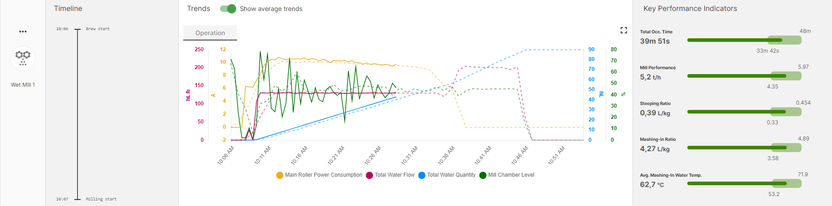

For brewers, the efficiency of their processes is decided in production: in balancing productivity, quality and sustainability. Plant operators are often dependent on selective sensor technology of the components. Temperature measurements, pressures and flow rates, however, neither provide an overall picture nor allow a forecast of the line's performance. If you also consider that raw material properties fluctuate and breweries often produce numerous types of beer at the same time, the complexity increases even further. The new software version gets brewers out of data silos and empowers them to master their data ecosystem through understandably presented analyses.

On the way to the Golden Batch

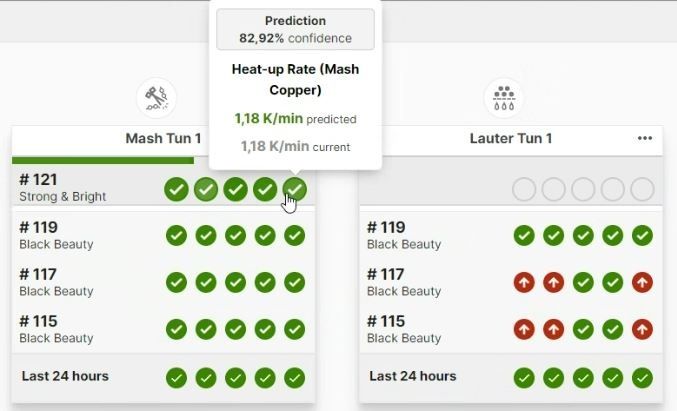

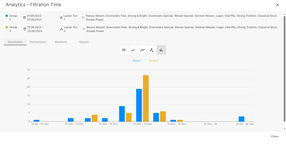

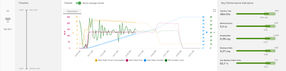

GEA InsightPartner does this by using predictive analytics - trend curves and forecasting models to predict performance indicators. Instead of making adjustments for the future only after a brew, the process can be improved directly as it progresses, for example by correcting energy recovery during wort boiling or identifying an imbalance in the energy storage system.

For performance problems that require operator attention, so-called predictive focus cards are created. They show dynamic optimization potential. Unlike control system alarms, they do not report process events, but instead indicate undesirable trends that affect productivity, quality or sustainability. This anomaly detection for the brewhouse is handled autonomously and continuously by GEA InsightPartner Brewery remotely. On request, GEA's process experts will join in and provide recommendations. With each recorded brew, the AI's predictive capability improves. In the long term, a brewery thus approaches the optimal brew with the best quality at the lowest resource input, the Golden Batch.

Flexible condition brewing replaces recipe-based brewing

Practical testing at well-known breweries shows that AI-supported corrective measures improve plant performance, increase energy efficiency, reduce operating costs and lead to greater safety. "GEA InsightPartner makes the results understandable for all working levels in breweries, where comparable, clear and reliably retrievable data was previously lacking," Schneeberger summarizes. "Advanced analytics is clearly the way for us to combine sustainability and decision-making in the day-to-day business of breweries. GEA's smart technology is an important milestone for breweries on the way to condition-based production - so that brewers can finally focus on brewing again."

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Other news from the department business & finance

Most read news

More news from our other portals

See the theme worlds for related content

Artificial intelligence (AI) for food and beverages

Artificial intelligence (AI) is optimizing the food and beverage industry through automated quality control and more accurate demand forecasting. AI plays a particularly important role in product development by analyzing taste preferences and market trends. This allows new products to be developed that are better tailored to consumer needs, increasing efficiency and customer satisfaction.

Artificial intelligence (AI) for food and beverages

Artificial intelligence (AI) is optimizing the food and beverage industry through automated quality control and more accurate demand forecasting. AI plays a particularly important role in product development by analyzing taste preferences and market trends. This allows new products to be developed that are better tailored to consumer needs, increasing efficiency and customer satisfaction.