Food 4.0 with 3D printing

Research team investigates the use of new raw materials for the targeted texturing of foods

Advertisement

food printers that print food paper with food colouring, for example, have been on the market for a long time. The leap from printing a two-dimensional surface to printing three-dimensional structures has also been successful: In order to offer astronauts more variations of their meal plans in space, NASA developed the first prototypes of a 3D food printer a few years ago. However, these are only used in market niches, e.g. to create personalised foods in very small quantities: a 3D text message made of marzipan, a 3D logo made of chocolate or creative eye-catchers in 3D.

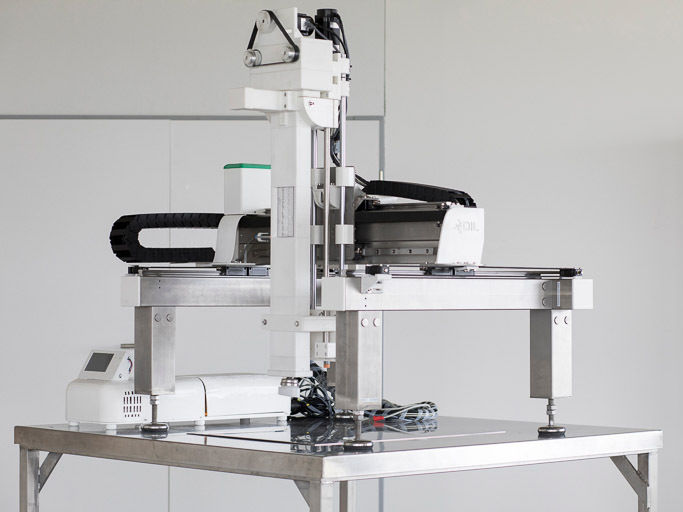

Because the applications of 3D printing for more complex foods based on starch- or protein-rich raw materials are still very limited: The approaches to shape bakery and pasta products, snacks or meat products using 3D printing are still in their infancy. This can essentially be attributed to the maturity of the technology and, above all, the lack of suitable printing materials or raw materials. To date, only raw materials that guarantee dimensional stability due to their high viscosity have been processed - the choice of materials is therefore clearly limited.

With the aim of promoting the revolutionary manufacturing process, this is the starting point for an FEI project of the Industrielle Gemeinschaftsforschung, which is being carried out by a team of researchers from Quakenbrück and Munich. First, the researchers systematically evaluate the printability of protein- and starch-containing materials using various key figures: The rheological, thermal and structural properties are then correlated with the printed image. Important factors here are, for example, the consolidation kinetics and the adhesiveness of the raw material so that the printed food product holds together when the layers are printed. The aim is to derive parameters for the assessment of materials and to define the concept of printability in general terms for raw materials.

In order not only to be able to print shapes, but also to generate specific textures, the researchers will investigate the influence of a thermal and mechanical treatment of the materials in the further course of the project. The layered structure of the food opens up completely new possibilities, e.g. to achieve fibrous structures (similar to a meat product) or a porous texture (similar to a breadcrumb). The potential to adjust the texture of foods using a printing process is therefore great. As a further milestone, the limits and possibilities of the 3D food pressure will be demonstrated by a targeted variation of the process parameters and the raw material composition and finally evaluated in a feasibility study.

Numerous companies across all industries will be able to benefit from the results. Since the production of food from the 3D printer is decentralized and does not require large systems, small and medium-sized companies in particular have excellent opportunities to offer individual products and stand out from the mass market.

Food 4.0 with 3D printing: Research team investigates use of new raw materials for targeted texturing of food products

Jörg Sarbach

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.