Natural Branding: The blue laser helps in the fight against plastic

It offers the food industry and retailers a safe and sustainable marking option with a positive Co2 footprint.

Advertisement

Supermarket chains have famously declared war on plastic bags, but when it comes to food packaging, retailers are taking their time. Why is that? Several needs are competing with each other here. On the one hand, singles in particular want ever smaller portions, which leads to more packaging, and there are many retailers who stick to plastic in terms of shelf life and protection. Only the pressure from consumers is increasing, as they are placing more and more value on loose goods in order to finally stop the packaging madness in Germany and to protect the earth from further pollution.

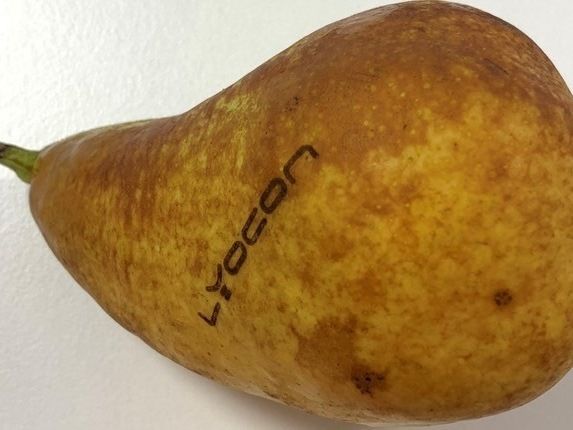

An organic pear: Natural Branding improves its Co2 footprint

RAYLASE GMBH

Consumers often do not understand why organic products such as cucumbers are shrink-wrapped in plastic. An anachronism! An affront to common sense? Back in 2018, Ocean Care in Switzerland, with a petition against plastic in organic produce, wrested a promise from the big grocers to change this. "It is pleasing to see that the proportion of plastic packaging has decreased at four of the Swiss suppliers surveyed. Coop reduced plastic packaging by 7.7%, Aldi managed an 8% reduction and Lidl achieved 8.7%." This is confirmed by the 2019 statistics of the organization dedicated to marine life. And this is due in part to an innovative technology that acts virtually like a laser tattoo: "natural branding." The process offers an effective ecological, fast, flexible, versatile and safe alternative to food marking, especially for organic fruit and vegetables, and even according to EU standards.

In the Natural Branding process, a laser, controlled by a deflection unit, removes the top pigment layer of the natural skin of the food. Natural Branding with laser does not require any additional color and impregnates the desired lettering or logo of the company directly onto the food using a focused beam of light. If this is done using blue laser light, it is a cold marking process that generates very little heat on the product. It has high absorption with good processing efficiency and low energy output. The method is used on garlic, onions, nuts, eggs, lemons, mangoes and sweet potatoes, for example. The technology has already been tested abroad - Australia has been using it since 2009. "Natural branding is risk-free. Marking with a laser system consisting of a blue laser and opto-mechanical deflection unit is particularly convincing due to its high reliability, long service life, low space requirement and a safe process. It also offers completely new possibilities for sustainable and resource-saving marking," emphasizes Wolfgang Lehmann, Product Manager at RAYLASE GmbH in Upper Bavaria.

The position can be determined very precisely and the laser spot can be focused very accurately. The beam can be precisely adapted to the shape of the food. This prevents damage, premature spoilage or contamination of fruit and vegetables. There is no loss of freshness, fragrance, taste, aroma or shelf life. Best of all, the energy required to mark the food is less than 1% of the energy required to produce a conventional sticker. And in addition, the CO2 emissions for laser marking are less than 0.2% of those of a sticker of comparable size. "With Natural Branding, we can save tons of plastic on organic food alone in Germany, and retailers can significantly improve their Co2 emissions," says RAYLASE CEO Dr. Philipp Schön, pleased with the advantages of the innovative process.

Unfortunately, the arguments of many supermarket chains still read long. For example, confusion with conventional goods is to be avoided, the packaging is supposed to prevent pesticide residues from conventional products from reaching organic goods, and from the retailer's point of view, protection simply seems better. In the course of regionality and consumer pressure, however, things are changing. Currently, eggs and nuts are being laser-branded in Bavaria. "But much more is possible," CEO Dr. Philipp Schön of RAYLASE is convinced, "because the limits of the process are set by the product alone. Provided the shell is not too thin or delicate, "natural branding" can be applied anywhere with good legibility and contrast of the lettering. And the labeled food can also be consumed without hesitation."

A shift in thinking is slowly emerging. "Laser marking" is increasingly being discovered by well-known food producers, packaging manufacturers and supermarkets such as Edeka in Germany, ICA in Sweden and M&S in the UK. Edeka plans to save 50 tonnes* of packaging material on fruit and vegetables through Natural Branding, and Rewe and Aldi are also looking at the suitability of more products.

It is true that organic certification is not an obligation to use particularly environmentally friendly packaging. "Consistently, however, the organic production of food, as long as it does not want to be perceived as "green washing", should also be followed by resource-saving ecological packaging, if possible. Natural branding creates maximum credibility here," emphasises Harnesh Singh, responsible for Sales & Marketing at RAYLASE. Doing away with too much plastic, paper, cellophane or trays is also good news for consumers who want to reduce their own carbon footprint and therefore like to reach for unpackaged goods.

So "clear the stage" for the new energy-saving talents from the laser industry! The blue 450 nm laser with scanning systems from 6 to 11 W is ready to make a lasting sustainable impression in the food market, especially with organic products. "The blue laser light in combination with our deflection units offers a safe and environmentally friendly solution for all kinds of marking applications. The market for "natural branding" is far from exhausted," Dr. Philipp Schön is certain.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.