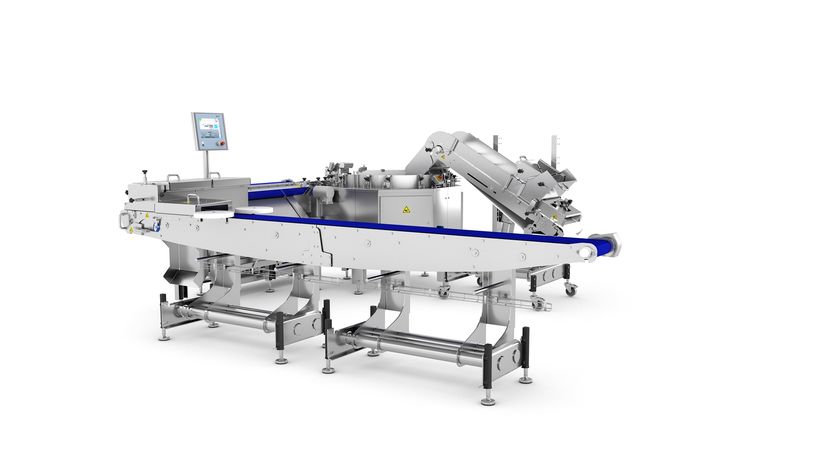

Automated loading of straight sausages - efficient, hygienic and gentle on the product

MULTIVAC has developed a hygienic and efficient solution, which is also gentle on the product, for the automated infeeding, loading and packing of straight and uniform sausages, and this solution was presented for the first time at IFFA 2016. The MULTIVAC Centrifuge Feeder (MCF) can be integrated seamlessly into packaging lines and enables handling costs to be reduced by up to 60 percent when compared with manual loading.

MULTIVAC Centrifuge Feeder (MCF)

source: MULTIVAC Sepp Haggenmüller SE & Co. KG

MULTIVAC Centrifuge Feeder (MCF)

source: MULTIVAC Sepp Haggenmüller SE & Co. KG

The solution comprises five high-performance components: the sausages are transported via an inclined conveyor to the centrifuge plate that is constantly turning. There they are orientated at the outside edge of the plate by the centrifugal force and are taken up individually from the centrifuge ring. Then a V conveyor transports them to a downstream compartment conveyor that carries each product, individually and precisely aligned in a separate compartment, to the handling module. There the gripper picks up the desired number of sausages and loads them into the pack cavity.

Up to 600 sausages per minute can be gently separated and loaded by the MULTIVAC Centrifuge Feeder. The output of the MCF can be adjusted as required via the rotation speed of 30 to 60 revolutions per minute. If even greater volumes are required, it is possible to use several of these modules on one packaging machine, so that virtually any capacity can be scaled up. This solution can be used very flexibly, and it is suitable for single-layer and multi-layer packs with any number and orientation of sausages.

MULTIVAC offers the Centrifuge Feeder in either a left or right rotating version, so that with a wide range of possible line layouts the optimum space utilisation can be achieved. All the components are produced in the MULTIVAC Hygienic DesignTM and can therefore be cleaned simply and reliably. Thanks to the automated process, human contact with the delicate products is also minimised – an important contribution to hygiene in the packaging procedure.

About MULTIVAC

MULTIVAC is one of the leading providers worldwide of packaging solutions for food products of all types, life science and healthcare products as well as industrial items. The MULTIVAC portfolio covers virtually all customers' requirements in terms of pack design, output and resource efficiency, and it includes vacuum packaging machines, traysealers, thermoforming packaging machines, labellers, quality control systems and automation solutions - right up to turnkey lines. The MULTIVAC Group has approximately 4,700 employees worldwide, with some 1,700 based at its headquarters in Wolfertschwenden. With more than 70 daughter companies the Group is represented on all continents. More than 1,000 sales advisors and service technicians throughout the world use their know-how and experience to the benefit of our customers, and they ensure that all installed MULTIVAC machines are utilised to their maximum. Further information can be found at: www.multivac.com.

Most read news

Other news from the department research and development

Get the food & beverage industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.