Decaffeinated coffee now also available for organic fans

Jana Köster from the FH Münster develops an ecological production process

Advertisement

Jana Köster was quite astonished when the delivery service placed a large ton of coffee beans in her laboratory. Green, raw, whole coffee beans, which were the basis for her research assignment: The aim was to find a process to decaffeinate these coffee beans ecologically and in accordance with the organic label. Up to now, caffeine has mainly been extracted from green coffee beans using organic solvents such as dichloromethane or ethyl acetate. This type is therefore not the first choice for organic fans. Nevertheless, they do not want to do without decaffeinated coffee - and a large coffee company turned to the professors at the Department of chemical engineering at Münster University of Applied Sciences for help. The assignment for Köster: to do basic research and develop a process in the laboratory to decaffeinate the coffee beans in an ecologically sound manner.

Jana Köster has developed an ecological process for the decaffeination of coffee beans in the laboratory.

FH Münster/Theresa Gerks

They are still gre the raw coffee beans before decaffeination. Afterwards they look dark, similar to the way they look after roasting - but they still have to be roasted.

FH Münster/Theresa Gerks

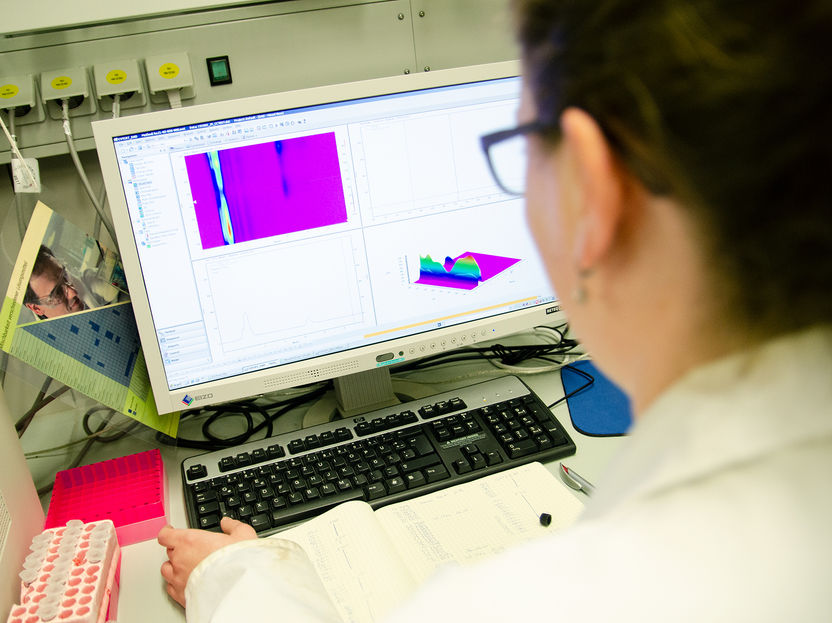

Jana Köster reads out on the computer what percentage of caffeine is still contained in the beans.

FH Münster/Theresa Gerks

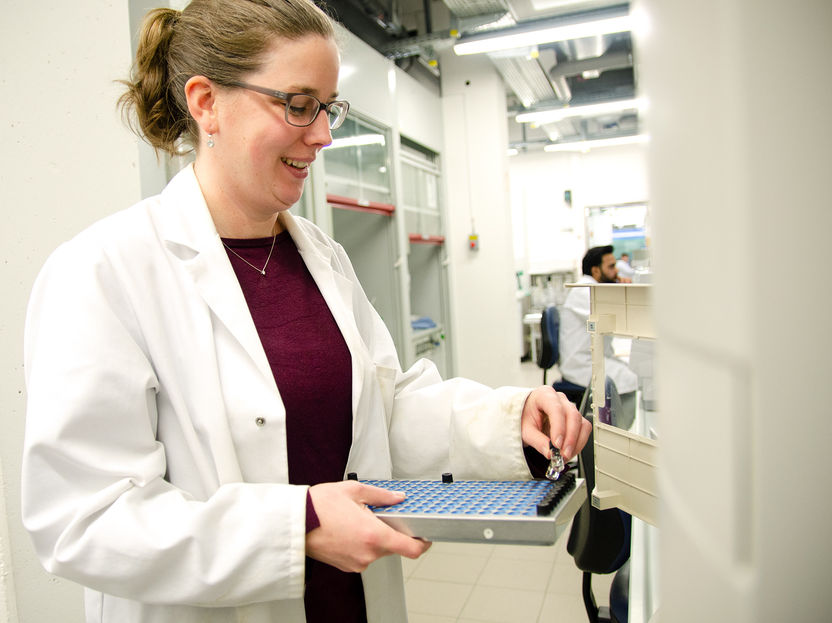

Jana Köster prepares the samples with the bean water for the analysis and thus checks how much caffeine has been dissolved from the beans.

FH Münster/Theresa Gerks

"Before, I had nothing at all to do with coffee," says the research assistant honestly and has to laugh almost a little about herself when she talks today about Arabica, Robusta and unroasted, raw, green coffee beans as a matter of course. But she doesn't have to be an expert on coffee either, because for her as a chemical engineer, her knowledge of process engineering is much more important. "I have carried out many experiments in the laboratory in order to implement the known cornerstones and develop the process based on them," explains the 27-year-old. And it looks like this: It pumps hot water, between 70 and 80 degrees Celsius, in a cycle over the beans. This flushes out the caffeine and aromas from the beans. "In principle, making coffee works the same way," explains Köster. It adds a solid, an adsorbent, to the coffee bean water, which is the main source of caffeine. All other substances remain in the water, which the bean eventually absorbs and reabsorbs. Ready is the decaffeinated bean, ready for roasting.

Decaffeinated means that less than 0.1 percent caffeine is contained at the end in the roasted state of the bean. "That was the hardest part, getting the last tenths of a percent to the border," remembers Köster. And besides the organic aspect, the taste of the coffee still had to be right.

"This process has been developed one step further, otherwise decaffeination often works selectively," said Prof. Dr. Andreas Wäsche from the Department of Chemical Engineering, who supervised Köster together with Prof. Dr. Volkmar Jordan during the two-year project work. "It's amazing that it works so well." And Köster is now working on ensuring that it also works industrially: She has just started as a project engineer at the cooperation partner of Münster University of Applied Sciences, where she is building the plant with which the coffee beans are ecologically decaffeinated using her self-developed process.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.