For perfect milk foam

Online measuring system ensures consistent milk quality

Advertisement

Project at the University of Hohenheim investigates factors influencing the foamability of milk & develops online monitoring system for early detection of product changes.

A delicious, creamy and fine-pored milk foam is an absolute must for them: Latte Macchiato, Cappuccino or even the Wiener Melange are enjoying ever-increasing popularity among German coffee drinkers. But time and again, individual production batches of otherwise flawless UHT milk cannot be satisfactorily frothed and lead to complaints to the manufacturers. The exact trigger for this is still unknown. In a research project, the University of Hohenheim in Stuttgart is getting to the bottom of the cause and developing an online monitoring system for the production of UHT milk. The aim is to detect as early as possible any product changes that lead to reduced foamability. With its funding of around 440,000 euros, it is one of the heavyweights of research in Hohenheim.

Foaming milk properly is an art in itself. The milk foam should be as creamy and fine-pored as possible and not collapse too quickly. When preparing coffee specialties in a café or bar, baristas like to use a fatty UHT milk, which must not only have good taste properties but also a consistent foaming quality throughout its entire shelf life.

However, individual production batches of UHT fatty milk do not have the desired barista quality: they do not foam as well as required by restaurants, catering companies and consumers. If complaints are made, the brand is avoided in the restaurant and catering sector or the products are no longer available in stores.

Milk is a complex natural product with a wide range of variations

Two teams from the University of Hohenheim are looking for causes and solutions. Prof. Dr.-Ing. Jörg Hinrichs from the Department of Dairy Science and Technology explains the problem: "UHT milk is a tried and tested product, the production of which has long been established and proven. But now additional requirements are being placed on this product which have not played a role until now - such as foamability.

"Milk is a natural product that can be subject to great fluctuations," he continues. "This applies not only to its composition, which is influenced by many factors such as feed or the season, but also to the question of how it is treated before processing. For example, after milking at the weekend, the milk may stand longer until further processing than during the week. This alone makes a difference. And preserved milk also changes during storage.

Many factors can influence milk foam formation

In addition, the exact cause of the unsatisfactory foamability is still unknown, explains Prof. Dr.-Ing. "Therefore, we have first of all developed a standard measuring procedure to find out what is not working and why. Because the various machines for milk foaming all function slightly differently, it is otherwise very difficult to find the reason. Then we can't tell whether the problem is due to the milk or the machine".

Based on the research results, he and his team derive recommendations for companies on how they can minimize product changes and produce UHT milk with the most consistent foaming behavior possible - starting with the treatment of the raw milk, through various processing steps such as homogenization and heating, to filling and storage.

Variety of ingredients that can change over time

"quality assurance in companies today uses numerous analytical methods to check whether the chemical, physical and microbiological properties of the finished packaged product are within certain limits," says Prof. Dr. Bernd Hitzmann from the Department of Process Analytics and Grain Science, explaining the issue his team is working on in the project.

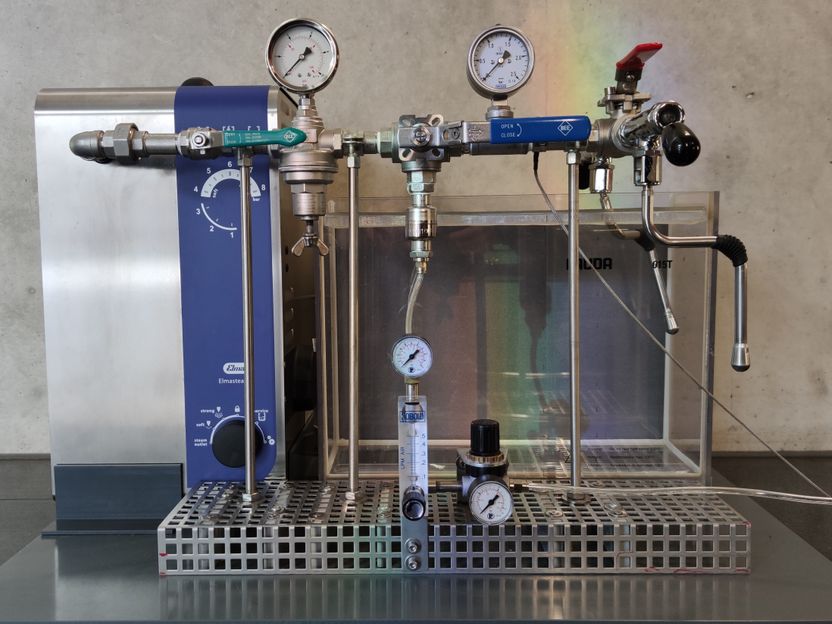

However, this cannot reflect the complexity of the processes leading up to the best-before date - a forecast of how the quality of the product will develop over time is therefore only possible to a limited extent. By combining different spectroscopic methods, such as Raman, near-infrared and fluorescence spectroscopy, it is possible to determine the concentration of various ingredients, among other things.

Automated analysis procedure helps to save costs

"Using the spectra we can even see which milk comes from which producer. But this also makes it possible to make predictions about quality characteristics up to the best-before date," says Prof. Dr. Hitzmann, explaining the advantages of the analysis method.

clipdealer

Universität Hohenheim / Darius Hummel

He continues: "If, for example, the spectral pattern deviates from the other batches or is very similar to the pattern of a complaint, the quality assurance department can react immediately without waiting for costly and time-consuming analysis results".

The long-term goal is to automate the analysis process. The system should then be integrated directly into the product flow before the last treatment step and/or filling and analyze the liquid product online.

But Prof. Dr. Hitzmann is thinking even further: "In principle, this procedure can also be transferred to other products and can be used, for example, to assess product properties or for the early detection of instabilities in various raw materials, semi-finished products and in the processing of other liquid products".