Currywurst in 30 seconds

Mechanical engineering students at Münster University of Applied Sciences automate preparation of snack dish

Advertisement

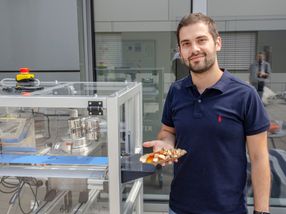

Currywurst on a conveyor belt - students at the Department of mechanical engineering at Münster University of Applied Sciences are making sure of that with their project work. Daniel Ruchser, Jonas Rosery and Wieland Wietheger have built a machine that automatically prepares the popular snack dish in just a few seconds. The only thing that - still - has to be done by hand is to grill the sausage and start the process.

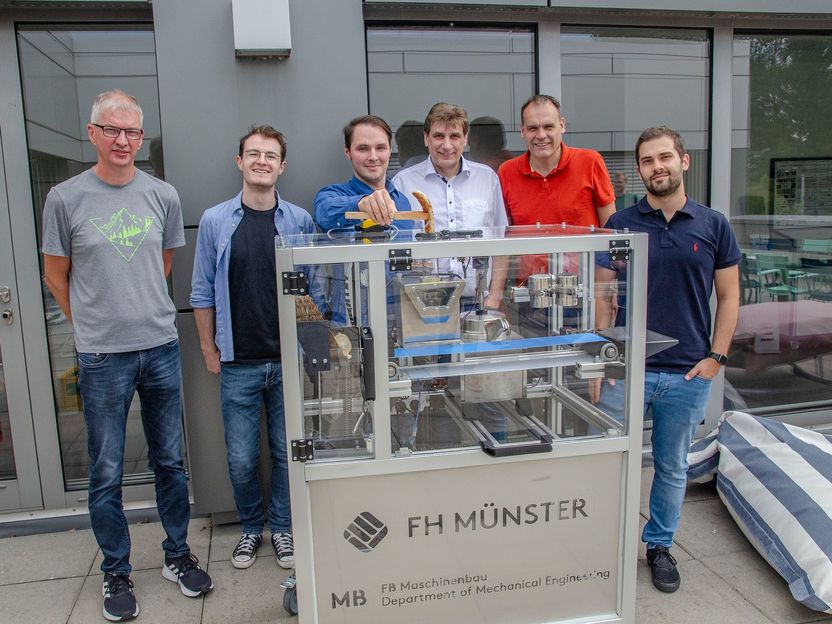

The project team behind the curry sausage machine (from left): Stefan Averkamp, Jonas Rosery, Wieland Wietheger, Prof. Dr. Eckhard Finke, Markus Lammers, Daniel Ruchser.

FH Münster/Frederik Tebbe

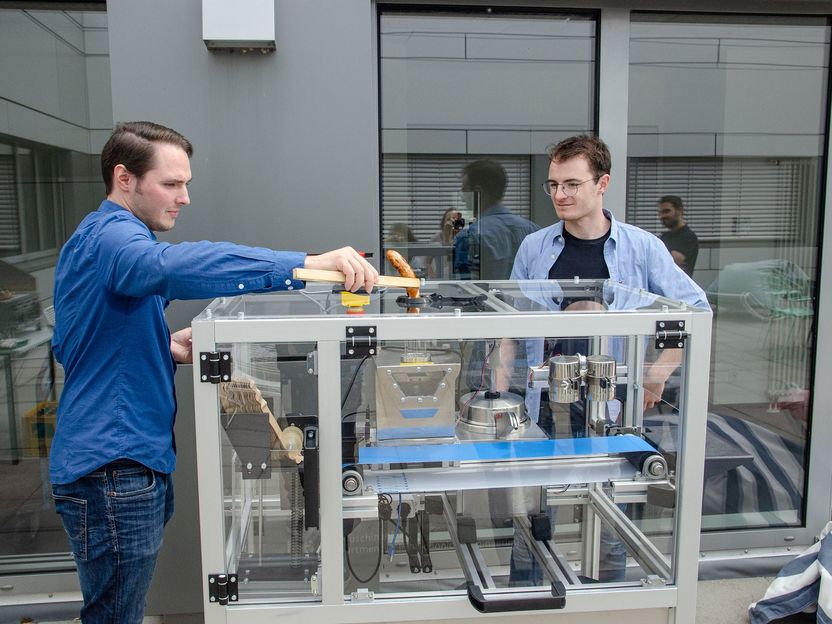

The grilled sausage activates a light barrier in the cutting device, then the preparation process begins fully automatically.

FH Münster/Frederik Tebbe

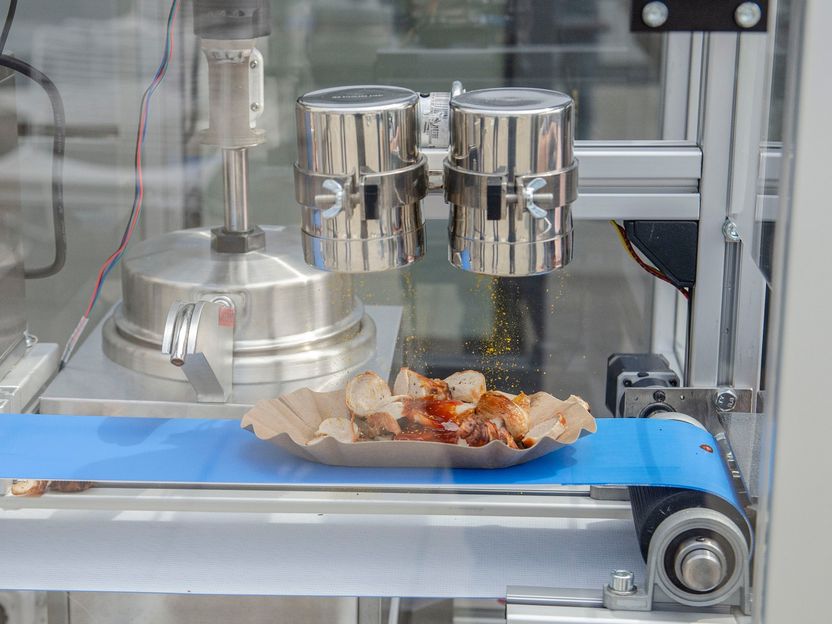

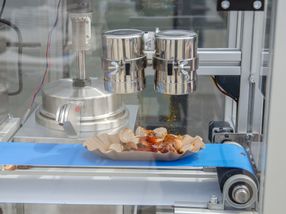

First the curry sausage is cut, then the sauce is added and finally the curry powder.

FH Münster/Frederik Tebbe

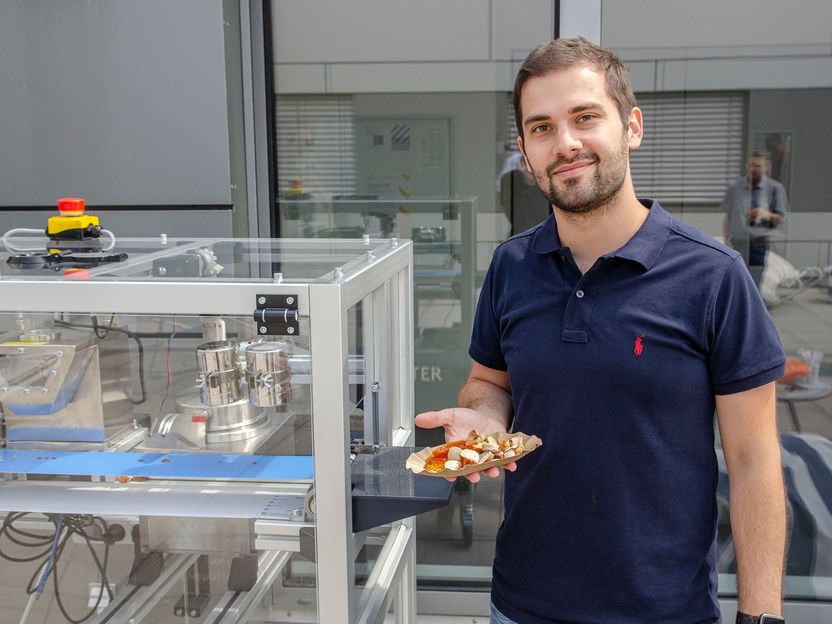

30 seconds later, the currywurst is ready.

FH Münster/Frederik Tebbe

Because as soon as the sausage is placed in the cutter, it activates a light barrier, setting the process in motion: a cardboard tray passes under the cutter by conveyor belt, and the minced sausage lands in it. At the next station, the sauce is added, followed by the curry powder - and the portion is ready to be eaten. It takes about 30 seconds to go through the process. "At the Christmas market, we were standing at a snack stand and thought to ourselves, 'You could actually automate this,'" explains Wietheger. "The final idea for the project then came during a conversation with Prof. Dr. Eckhard Finke." Mechanical engineering dean Finke and research assistants Markus Lammers and Stefan Averkamp then supervised the work. The master's program at the department provides for such project work - and the university should now continue to benefit from the machine. "The students have done an excellent job with the project. It shows how close to real life mechanical engineers work, what you learn in our studies and what you can do with it," says Finke. "We could imagine using the machine at first-semester events or on get-to-know-you days." In addition, it could also be further developed in follow-up projects - after all, not everything runs fully automatically yet. It would also be conceivable to integrate a grill into the process.

"From the idea to the implementation, we did everything ourselves," says Ruchser. "We both selected the parts, took care of the electronics and, for example, came up with the stepper motor that drives the conveyor belt." There was also support from the 3D printers in the Computer Simulation Lab, the MakerSpace and the Machine Tools and Manufacturing Technology Lab on the Steinfurt campus. "Working on the project, we learned a lot. You have to work in a solution-oriented way and bring together what you went through in your studies. That helped us a lot," Rosery said. By the way, working on the machine hasn't spoiled their appetite for currywurst: "Actually, it's only increased their appetite," says Wietheger with a grin.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.