Scalable production technique for low-calorie sugar substitute

Advertisement

Scientists at the University of California, Davis, in partnership with the Mars Advanced Research Institute, have announced a significant breakthrough in the production of low-calorie sugar substitutes, such as allulose. This discovery could help address one of the primary obstacles to the widespread adoption of these alternatives: production costs.

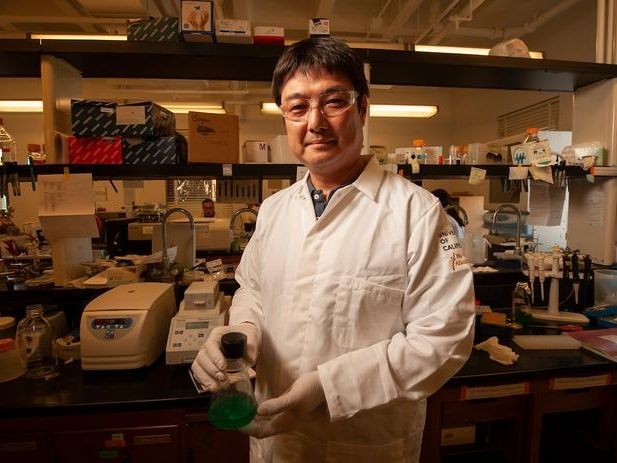

Professor Shota Atsumi, UC Davis Department of Chemistry, led a team that found a new way to coax microbes into making allulose, a potential substitute for table sugar. The work was conducted in collaboration with the Mars Advanced Research Institute.

UC Davis

Allulose, also known as D-psicose, is a naturally occurring rare sugar that provides a viable alternative to sucrose (table sugar). It has a similar taste, texture and functionality, making it an attractive option for those seeking to reduce their sugar intake. By activating a natural process in a microorganism, researchers have developed a method for high-yield and high-purity production through precise fermentation. This advance has the potential to greatly enhance the affordability and accessibility of these products.

Allulose provides nearly 70% flavor and sweet taste as sucrose, yet it is minimally metabolized as it passes through the body. By incorporating it into food products, individuals can reduce their calorie intake from sugar while still satisfying their desire for sweet flavors. Additionally, allulose has an imperceptible effect on blood glucose and insulin levels.

“Allulose is a great alternative to sugar, but we have not had a cost-effective way to manufacture it,” said Shota Atsumi, professor of chemistry at UC Davis and corresponding author on the paper published Oct. 14 in npj Science of Food. “Our new method is efficient, economically feasible and could be scaled up for commercial production.”

The new approach has a more than 99% theoretical yield with high purity, and therefore only requires minimal processing to isolate the desired product. Current methods of allulose production are normally limited to much lower levels of yield and purity, requiring expensive separation techniques to isolate allulose from the glucose and fructose starting material.

Redirecting existing process

Atsumi, Ph.D. candidate Jayce Taylor, Professor Justin Siegel and a number of co-workers in the Department of Chemistry and from Mars Advanced Research Institute looked for a more efficient way to manufacture allulose. They found an industrial microorganism that has the enzymes to make allulose — it just isn’t using them in that way. They were able to edit the organism’s metabolism to get the cells to convert glucose into allulose. The cells consume all the glucose they are fed and convert it to allulose with a noteworthy concentration, a yield of over 60%, and purity of over 95%, outperforming the existing production methods.

“Once flux was redirected, it turns out the cells have everything they need to do it; they just needed to be turned on and undesired pathways turned off,” Atsumi said.

UC Davis has filed patent applications on the process and modified organisms. Researchers are working with a commercial partner to discuss scaling up the process.

Additional co-authors are Dileep Sai Kumar Palur, Angela Zhang, Jake Gonzales, Augustine Arredondo, Timothy Coulther, Amiruddin Bin Johan Lechner, Elys Rodriguez and Oliver Fiehn at UC Davis; and John Didzbalis, Mars Incorporated, McLean, Virginia.

The work and research by UC Davis were supported and funded by Mars, Incorporated.

Original publication

Jayce E. Taylor, Dileep Sai Kumar Palur, Angela Zhang, Jake N. Gonzales, Augustine Arredondo, Timothy A. Coulther, Amiruddin Bin Johan Lechner, Elys P. Rodriguez, Oliver Fiehn, John Didzbalis, Justin B. Siegel, Shota Atsumi; "Awakening the natural capability of psicose production in Escherichia coli"; npj Science of Food, Volume 7, 2023-10-14