EPR Sensor on a Chip Boosts Olive Oil & Beer Quality Control

Advertisement

The first sign of spoilage in many food products is the formation of free radicals, which reduces the shelf-life and the overall quality of the food. Until now, the detection of these molecules has been very costly for the food companies. Researchers at HZB and the University of Stuttgart have developed a portable, small and inexpensive 'EPR on a chip' sensor that can detect free radicals even at very low concentrations. They are now working to set up a spin-off company, supported by the EXIST research transfer programme of the German Federal Ministry of Economics and Climate Protection. The EPRoC sensor will initially be used in the production of olive oil and beer to ensure the quality of these products.

Michele Segantini demonstrates the compact size and the portability of one of the EPRoC-Sensor with a permanent magnet.

Luca Segantini

When food goes bad, highly reactive molecules are produced, so called free radicals. The food industry has to go to great lengths to detect these molecules, either with chemical methods or via the only direct method, called electron paramagnetic resonance (EPR). But conventional EPR machines use electromagnets which do not allow battery operation and are expensive to buy and operate.

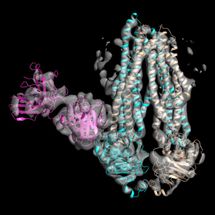

EPR-on-a-chip sensor

The new start-up company SpinMagIC now offers an EPR sensor that fits on a small chip. “We will produce small, portable and affordable EPR devices based on the combination of a microchip and permanent magnets that can be tailored to the customer's needs," explains physicist Michele Segantini (HZB), who is about to complete his PhD in Prof. Klaus Lips' department. In addition to Segantini, the founding team includes electrical engineer Anh Chu, physicist Belal Alnajjar, both at the University of Stuttgart in the team of Professor Jens Anders, and economist Jakob Fitschen.

The development of the ERPoC goes back to an idea by Klaus Lips (HZB) and Jens Anders (University of Stuttgart), which won the HZB Technology Transfer Award in 2019. Further development was then funded by the German Federal Ministry for Education and Research BMBF. “A lot has happened since then, so that we can now plan a spin off company”, says Segantini. While the team at the University of Stuttgart optimised the 'hardware', Segantini investigated where this invention could be used in the market.

“We see a huge potential for applications, initially mainly in food production," says Segantini. During his PhD, he contacted a wide range of industries and identified olive oil producers and breweries as pilot customers. Until now, these companies have tested their products using elaborate chemical methods, which produce relevant amounts of toxic waste. "EPRoC is not only much more sensitive, it is also less time-consuming, so samples can be analysed repeatedly throughout the process. This provides additional insights that can be used to optimise production processes to extend the shelf-life and oxidative resistance of the products”, Segantini points out.

In the future, the founders plan to adapt their product also to other areas of application, such as medical diagnostics, drug development, semiconductor technology and battery monitoring.

Other news from the department science

Most read news

More news from our other portals

Something is happening in the food & beverage industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.