Foodtech start-up Yeastup starts production on an industrial scale

Vegan premium ingredients made from brewer's yeast: functional for sports nutrition and egg replacement

Advertisement

A special door opened on St. Nicholas Day in the canton of Bern: after around two years of renovation and development, the multi-award-winning start-up Yeastup celebrated the opening of its production plant in Lyss with employees, customers and friends. At the state-of-the-art former dairy site, 40 hectoliters of surplus brewer's yeast per hour can currently be fully utilized as a valuable resource. Yeastup is currently preparing Series A financing for the further scale-up.

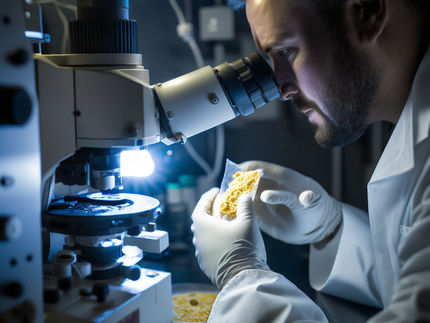

The team led by Yeastup founder Daniel Gnos invested 10 million Swiss francs in venture capital and several years of intensive research in cooperation with the University of Applied Sciences and Arts Northwestern Switzerland (FHNW) to develop the patented process with which Yeastup extracts the functional yeast protein Yeastin® and the fiber ingredient UpFiber® beta-glucan from surplus brewer's yeast.

Ideal composition: ecological, versatile, vegan, healthy

The convincing result could be tasted at the opening in the form of the first vegan protein bars. The yeast proteins perform similar functional tasks to collagen hydrolyzate, which is used in many conventional recipes to improve texture, moisture retention and mouthfeel. "Our Yeastin® NUTRA enables the development of bars with a soft, candy-bar-like consistency and without any animal ingredients," explains Gnos and adds: "This application serves as a showcase for the technological potential and versatility of our protein fractions. Samples are available on request."

Yeastin® offers an excellent alternative to animal and vegetable proteins due to its significantly lower ecological footprint and excellent nutritional properties. It can also be used as an emulsifier and egg substitute in baked goods in many product recipes.

40 hl of brewer's yeast per hour, and rising

At the Lyss site with 16 employees, Yeastup now has a fully equipped food production facility covering around 1,700 m², whose capacity was expanded from 1,600 to 4,000 liters of yeast per hour this year following the start of production for the first samples and pilot batches. Regular production at industrial level will start at the beginning of 2026, with 24/7 operation.

Yeastup is still in the growth phase and is currently preparing another Series A financing round. The aim is to ramp up production following the successful capacity expansion and accelerate international market development. "Following the completion of Innosuisse funding and technology financing in 2025, we are now focusing on scaling, product development and the establishment of long-term strategic partnerships," says Gnos, outlining his plans. He is very confident about the next round: "Now that Yeastup is ready for industrial operation and the first customer projects have been completed, it is a very good time for investors to participate in Yeastup and actively help shape the next stage of growth."

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Other news from the department Production

Most read news

More news from our other portals

Something is happening in the food & beverage industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.